Portwest FR22 Navy Insect Repellent Flame Retardant Coveralls

The Portwest FR22 Navy Insect Repellent Flame Retardant Coveralls are designed to keep variety of insects away, whilst also being able to provide flame retardant protection, making them excellent for a variety of work environments. Tested and certified to EN ISO 11612, EN ISO 11611 AND EN 1149 - 5, workers wearing the Portwest FR22 can receive total peace of mind that they are fully protected from hazardous environments in the workplace.

What Can the Portwest FR22 Navy Coveralls Do for Me?

The coveralls have several helpful features:

- Insect Repellency: The Portwest FR22 coveralls have an odourless insect repellent formula which is tightly bound to its fibres to keep a variety of insects away

- Flame Resistant: The coveralls offer inherent protection against radiant, convective and contact heat, as well as shielding the wearer from welding related hazards such as splashes of molten metal

- Anti-Static: Carbon fibre content of the fabric confers inherent anti-static properties

- Functional: Two-way zip provides quick and easy access, knee pad pockets increase wearer comfort, radio loops allow for easy clipping of radio and ten pockets supply ample storage

- Mobility: The lightweight fabric and design of the coveralls allows for full freedom and range of movement

The coveralls are constructed from the inherently flame resistant and anti-static fabric Bizflame Plus. The innovative material offers excellent durability, and the cotton fibres make it soft and comfortable to the touch.

What is Portwest's Bizflame Plus range?

Items made of Porwest's BizFlame Plus use highly innovative flame-resistant fabric with added anti-static properties, ensuring you are protected when working in hazardous environments.

Durable and Long-Lasting Fire-Resistant Coveralls

Constructed from 99% cotton and interwoven with 1% carbon fibres, the Portwest FR22 Work Coveralls have excellent tear and tensile strength for durability. Carbon fibres generally have excellent tensile properties, low densities, high thermal and chemical stabilities, good thermal and electrical conductivities, and excellent creep resistance.

Who Can Use the Portwest Heat Resistant Coveralls?

The Portwest coveralls are designed for use in environments where there is a risk of flames, heat and welding related hazards such as molten metal splashes. Thanks to its anti-static properties the jumpsuit is also suitable for settings where there is a risk of a build-up of static charge leading to an explosion or an electric shock. As the garment is also insect repellent, the coveralls are also suitable for a range of work environments where insects/bugs are around.

Some suitable environments and professions to wear the Portwest FR22, include:

- Petrochemical refineries

- Sheet metal workers

- Mechanics

- Engineers

- Assembly

- Electricians

- Construction

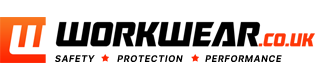

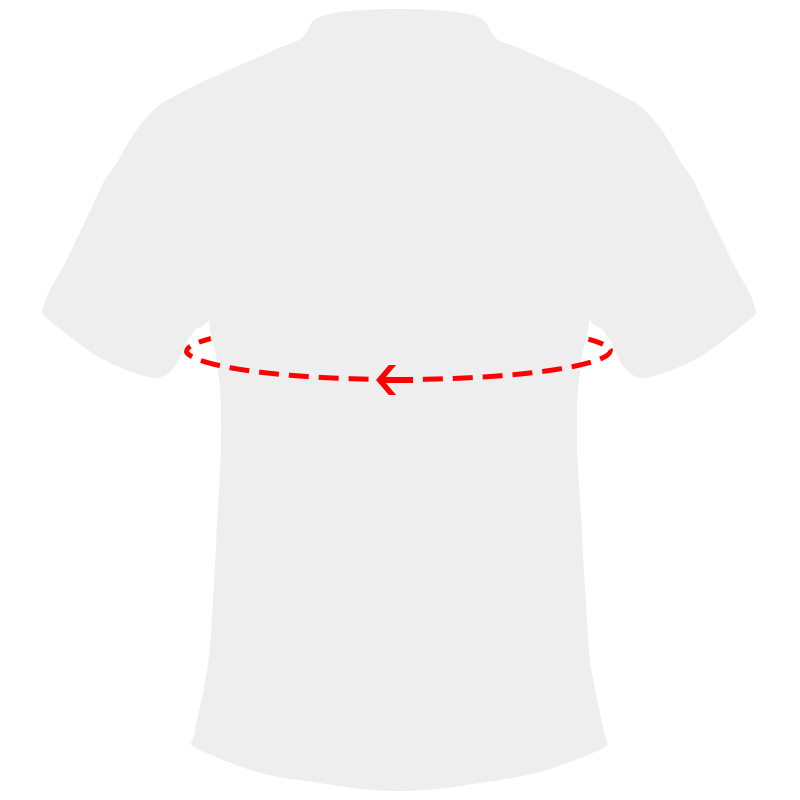

Which Size Portwest Work Coveralls Is Right for Me?

To find the correct size for you please measure yourself around the waist and chest as illustrated in the images below, then find the corresponding size with reference to the table. Next please select this size from the drop-down menu at the top of the page.

| Size | Chest Measurement (cm) | Waist Measurement (cm) |

| Small | 92 - 96cm | 76 - 80cm |

| Medium | 100 - 104cm | 84 - 88cm |

| Large | 108 - 112cm | 92 - 96cm |

| Extra Large | 116 - 124cm | 100 - 104cm |

| XX-Large | 128 - 132cm | 108 - 112cm |

| XXX-Large | 136 - 140cm | 116 - 120cm |

Please Note: The inside length for all sizes of the Portwest FR22 Navy Flame Retardant Coveralls come in a regular 31" inside leg length only.

What Certifications Have the Portwest Coveralls Received?

The coveralls have been rigorously tested so you can be certain of your absolute safety at work.

- EN 11612:

- A1: Limited flame spread

- A2: Limited flame spread, hemmed

- B1: Convective heat (scale 1-3)

- C1: Radiant heat (scale 1-4)

- E2: Molten iron splash (1-3)

- F1: Contact heat

- EN ISO 11611

- EN 1149:

- 5: Protects against electrostatic discharge in case of an explosion

- ASTM F1959/ F1959M - 12 ATPV = 9.1CAL/CM²

What Do These Certifications Mean?

- EN 1149-5: This standard demonstrates whether a garment protects against electrostatic discharge in environments such as petrochemical refineries where there is a risk of explosion

- EN 11612: This standard determines whether a garment offers protection against heat and flames, and whether this protection extends to convective, radiant or contact heat

- EN 11611: This standard shows whether an item of clothing is suitable for welding or similar tasks and will protect the wearer from heat and metal splashes

- ASTM F1959: This standard determines the arc rating of a garment, which is the amount of energy needed to pass through the fabric to cause a second or third degree burn

The coveralls offer protection from welding hazards, such as molten metal, as well as radiant, convective and contact heat. A carbon fibre element in the fabric confers inherent anti-static properties on the garment, so you will be protected from the effects of electrostatic discharge.

Is Further Information Available on These Certifications?

If you would like to find out more about the standards mentioned here please read one of our blogs on the subject:

What Are the Key Features of the Portwest Anti-Static Coveralls?

- Lightweight work coveralls protect against heat, flames, static

- Insect repellent fabric keeps variety of insects away

- Hook and loop cuffs allow for a secure fit at the at the wrists

- Sew on flame resistant industrial wash tape

- Radio loops allow for easy clipping of radio

- 10 pockets for ample storage space

- Two-way zip for quick and easy access

- Knee pad pockets facilitate knee pads

- Rule pocket

- UV protection fabric blocks out 98% of UV rays

- CE certified and UKCA marked

- CE-CAT III

How Should I Care for the Portwest Coveralls?

- Wash at temperatures of 60°C or below

- Max 50 washes

- Do not bleach

- Tumble dry at low settings

- Iron at medium temperatures

- Do not dry clean

Technical Specifications

- Materials: Bizflame Plus: 99% Cotton, 1% Carbon Fibre 210g

Conformity Statement

.jpg)

.jpg)