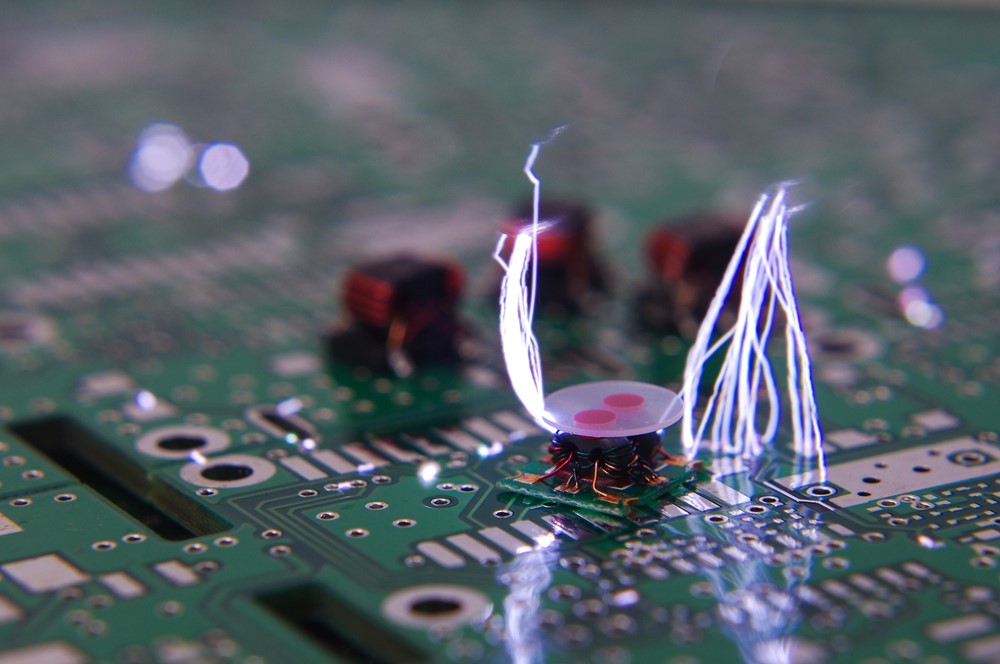

| Anti-Static Workwear: What Do I Need to Know?17 February 2020 Electrostatic discharge can cause all sorts of interesting effects, but when it comes to static protection at work, it becomes a matter of protecting the safety of both the worker and their equipment. Static charges can cause a range of issues, including catastrophic explosions resulting from minute electrostatic discharges.

Humans often don't feel electric shocks at lower voltages, however these undetectable discharges can cause irreparable damage to electronics. As our industries and technologies advance the importance of anti-static PPE is only increasing. Which Professions Require Anti-Static PPE?Many professions require anti-static PPE, here is a short list of examples:

What Is Static Charge?Static charge is easiest to think of as a kind of imbalance on the surface of a material, where the electric charge is either positive or negative. The repeated contact of two items, for example a balloon and your hair, can cause electrons to move from one to the other resulting in a positive or negative electric charge for both of the surfaces. However, contact is not the only way in which a surface becomes statically charged. What Leads to a Build-Up of Static Charge in Modern Day Industries?Electrostatic discharge is far more common in modern industrial environments for two main reasons:

What Is Electrostatic Discharge?If two statically charged objects, one negative and one positive, come into contact then this can result in a sudden flow of electricity between them. This flow of electricity is electrostatic discharge, which can result in something as large-scale as lightening to something as small-scale as an entirely silent and invisible discharge. What Is the Difference Between Electrostatic Discharge and an Electrical Arc?For clarification it is worth noting that an electrostatic discharge can create, but does not necessarily have to create, an electric arc. For example, lightening is both an electrostatic discharge and an electric arc. However, some electrostatic discharges are gradual, invisible and continuous, and in these cases an arc flash does not occur. What Are the Dangers of Electrostatic Discharge?Electrostatic discharge can lead to three important negative consequences: Risk of Bodily HarmIf a machine operator receives a shock from the product they are working with they will suffer with the pain of the shock, and it might easily throw them off balance resulting in further injury. Simply standing in the electric field of a charged object can result in this effect. If a machine does cause an electric shock it must be switched off for an inspection, which results in wasted time and productivity. Risk of Damaging ElectronicsEven in cases where the voltage of the electrostatic discharge is extremely low, products such as circuit boards and microchips can be irreparably damaged by electrical overstress. Risk of ExplosionA tiny spark caused by a small electrostatic discharge can easily function as an ignition source in combustible environments. These explosions can be extremely dramatic, and have resulted in industrial tragedies such as the events occurring in a grain silo in the Southwest of France and a paint plant in Thailand. An Introduction to Anti-Static StandardsThere are two essential Anti-Static PPE standards, one for protecting the wearer, the other for protecting electronics. EN 1149 - To Protect the WorkerGarments which conform to EN 1149 prevent static build up with the purpose of averting electrostatic discharge from igniting in an explosive atmosphere. These garments are tested in the most combustible atmosphere possible; a mixture of gas, hydrogen and air. Clothes can conform to the EN 1149-5 standard in one of two ways:

Usually a worker's uniform will require more than just the EN 1149 garment standard:

IEC 61340 - To Protect the EquipmentThis standard refers to gloves which will effectively protect electronic devices from electrostatic phenomena. It has been shown that 60 - 75% of defective electronic devices were damaged by electric overstress. If a pair of gloves are certified as 61340 it indicates that:

The IEC 61340 standard is often followed by a value of the following form: R: 6.0x10⁵ Ω – 5.4x10⁸ Ω. This measures the electric resistivity of the fabric, and gloves complying with this standard must have a value within a certain range. A Case Study: Portwest Anti-Static Flame Resistant Work Shirt Let's put this into practice. As an example we can use the Portwest FR11 Anti-Static Flame Resistant Work Shirt.

The FR11 Shirt has received compliance in accordance with the following standards:

EN 1149 The shirt conforms to EN 1149, meaning that it prevents static charge from building up. This shirt features carbon fibre woven into the fabric, and this conductive material harmlessly releases the static charge. EN 11612 The shirt offers protection from radiant, convective and contact heat, meaning that if there is an explosion it can help shield you from the thermal hazards. A Second Case Study: Ejendals Tegera 30 ESD Anti-Static Electronics Work GlovesNow let's look at a pair of gloves. A suitable example would be the Ejendals Tegera 30 ESD Anti-Static Electronics Work Gloves.

The gloves have received the following relevant standard:

IEC 61340 The gloves can be worn to handle electronics without fear that the electronics will be damaged by electrostatic discharge. The electric resistivity of the fabric is within the acceptable range. Where Can I Find More Anti-Static Workwear?For further information and anti-static work wear have a look through our Anti-Static Workwear category! If you have any questions or anything to add, then we would love to hear from you. Please leave a comment below! |